Liquid Heating

| 1400 Series | |

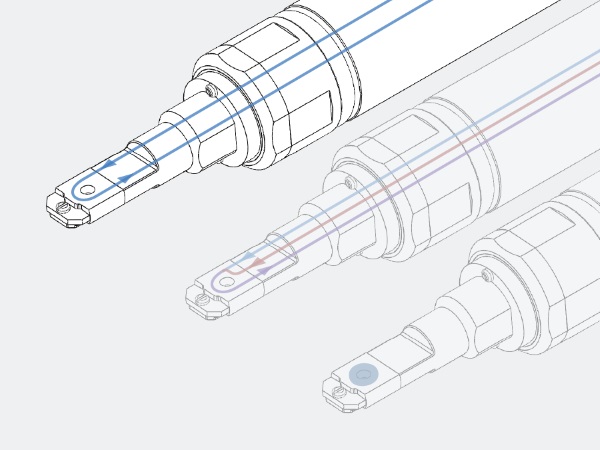

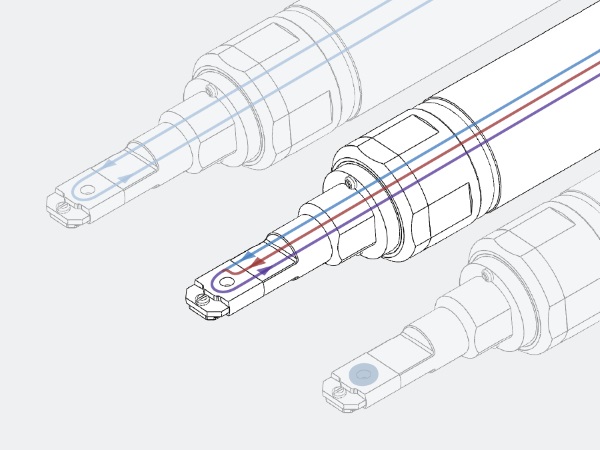

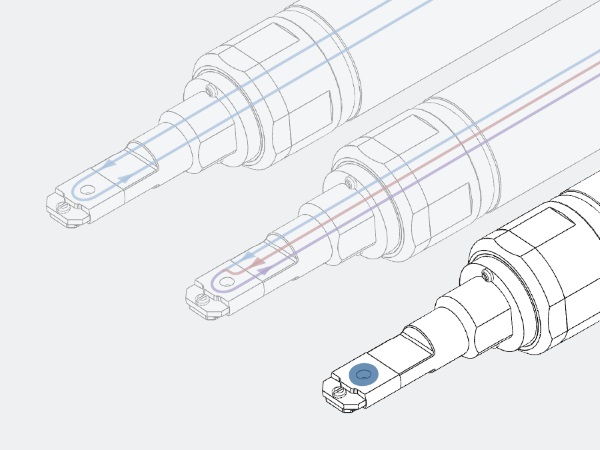

| Number of Inlets | 1 or 2 depending on model, single outlet |

| Biasing Contacts | 4 |

| Tubing Type | User-replaceable microfluidic tubing |

| Delivery System | Variable speed liquid delivery system |

| Tip Type | Removable tip |

| Flow Type | Continuous flow or static liquid |

| EDS Compatible | Yes |

| TEM Compatibility | TFS/FEI, JEOL, Hitachi, Zeiss |

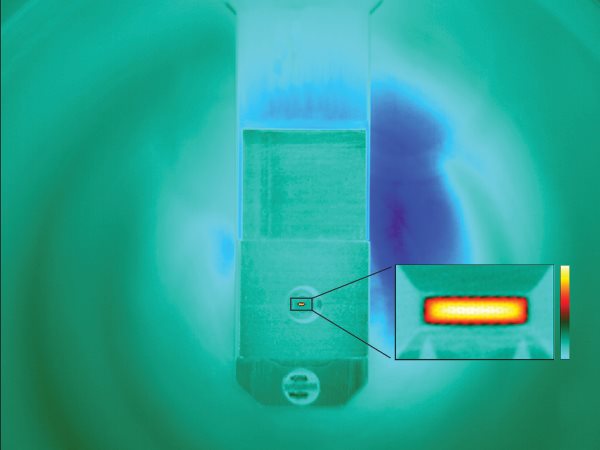

Direct visualization of compartementalization in adaptive microgels

Researchers at RWTH Aachen University, DWI − Leibniz-Institute for Interactive Materials and theHelmholtz-Zentrum Berlin für Materialien und Energie have visualized compartementalization in adaptive microgels using liquid-heating TEM. Compartmentalization in soft materials is important for segregating and coordinating chemical reactions as well as sequestering (re)active components. The authors show the direct visualization of different compartments within adaptive microgels using a combination of in-situ electron and fluorescence microscopy. By acquiring an unprecedented levels of structural details they address the challenge of reconstructing 3D information from 2D projections for nonuniform soft matter as opposed to monodisperse proteins. They also show the thermally induced shrinkage of responsive core–shell microgels in water. Applying the methods used in this work more broadly open doors for in-situ studies of soft matter systems and their application as smart materials.

Reference: Arjan P. H. Gelissen, Alex Oppermann, Tobias Caumanns, Pascal Hebbeker, Sarah K. Turnhoff, Rahul Tiwari, Sabine Eisold, Ulrich Simon, Yan Lu, Joachim Mayer, Walter Richtering, Andreas Walther, and Dominik Wöll. “3D Structures of Responsive Nanocompartmentalized Microgels,” Nano Letters (2016)

Abstract

Copyright © 2016 American Chemical Society

Nanoscale galvanic replacement reactions of Ag nanocubes

Liquid Heating platform was to observe the nucleation, growth, and coalescence of voids inside the nanocubes during the GR reaction with Au ions at different temperatures. In the experiment, the nanocube solution was drop-casted onto the heater chips and sealed in the liquid holder using the bottom spacer chips. The Ag nanocubes were heated to a desired temperature before flowing the solution. The Ag nanocube studied were stable and remained in cuboid shape after heating at ~ 90 degree Celsius during imaging.

Left: Movie showing the morphological evolution of Ag nanocubes during galvanic replacement reaction at 23°C.

Reference: See Wee Chee, Shu Fen Tan, Zhaslan Baraissov, Michel Bosman & Utkur Mirsaidov. “Direct observation of the nanoscale Kirkendall effect during galvanic replacement reactions,” Nature Communications (2017). Abstract

Video Copyright ©2017 Macmillan Publishers Limited, part of Springer Nature

Top page banner: detail of Video Copyright ©2017 Macmillan Publishers Limited, part of Springer Nature

Edit| Serin Lee, Nicholas M. Schneider, Shu Fen Tan, and Frances M. Ross. “Temperature Dependent Nanochemistry and Growth Kinetics Using Liquid Cell Transmission Electron Microscopy.” ACS Nano (2023) | Abstract |

| Wenhui Wang, Tanmay Ghosh, Hongwei Yan, Ivan Erofeev, Kun Zhang, Kian Ping Loh, and Utkur Mirsaidov. “The Growth Dynamics of Organic–Inorganic Metal Halide Perovskite Films.” J. Am. Chem. Soc. (2022) | Abstract |

| Albert Grau-Carbonell, Sina Sadighikia, Tom A. J. Welling, Relinde J. A. van Dijk-Moes, Ramakrishna Kotni, Maarten Bransen, Alfons van Blaaderen, and Marijn A. van Huis. “In Situ Study of the Wet Chemical Etching of SiO2 and Nanoparticle@SiO2 Core–Shell Nanospheres.” ACS Applied Nano Materials (2021) | Abstract |

| Shu Fen Tan, Kate Reidy, Julian Klein, Ainsley Pinkowitz, Baoming Wang, and Frances M. Ross. “Real-time imaging of nanoscale electrochemical Ni etching under thermal conditions.” Chem. Sci. (2021) | Abstract |

| David A. Shapiro, Sergey Babin, Richard S. Celestre, Weilun Chao, Raymond P. Conley, Peter Denes, Bjoern Enders, Pablo Enfedaque, Susan James, John M. Joseph, Harinarayan Krishnan, Stefano Marchesini, Krishna Muriki, Kasra Nowrouzi, Sharon R. Oh, Howard Padmore, Tony Warwick, Lee Yang, Valeriy V. Yashchuk, Young-Sang Yu, and Jiangtao Zhao. “An ultrahigh-resolution soft x-ray microscope for quantitative analysis of chemically heterogeneous nanomaterials.” Sci. Adv. (2020) | Abstract |

| Mi Yoo, Young-Sang Yu, Hyunwoo Ha, Siwon Lee, Jin-Seok Choi, Sunyoung Oh, Eunji Kang, Hyuk Choi, Hyesung An, Kug-Seung Lee, Jeong Young Park, Richard Celestre, Matthew A. Marcus, Kasra Nowrouzi, Doug Taube, David A. Shapiro, WooChul Jung, Chunjoong Kim, and Hyun You Kim. “Tailored oxide interface creates dense Pt single-atom catalysts with high catalytic activity.” Energy Environ. Sci. (2020) | Abstract |

| Shu Fen Tan, See Wee Chee, Zhaslan Baraissov, Hongmei Jin, Teck Leong Tan, and Utkur Mirsaidov. “Intermediate Structures of Pt–Ni Nanoparticles during Selective Chemical and Electrochemical Etching.” J. Phys. Chem. Lett. (2019) | Abstract |

| Shu Fen Tan, Geeta Bisht, Utkarsh Anand, Michel Bosman, Xin Ee Yong, and Utkur Mirsaidov. “In situ Kinetic and Thermodynamic Growth Control of Au-Pd Core-Shell Nanoparticles.” Journal of the American Chemical Society (2018) | Abstract |

| Jeung Hun Park, Tommy Watanabe, Ainsley Pinkowitz, David J. Duquette, Robert Hull, Daniel A. Steingart, and Frances M. Ross. “In situ EC-TEM Studies of Metal Thin Film Corrosion in Liquid Solutions at Elevated Temperatures.” Microscopy & Microanalysis (2018) | Abstract |

| See Wee Chee, Shu Fen Tan, Zhaslan Baraissov, Michel Bosman, and Utkur Mirsaidov. “Direct observation of the nanoscale Kirkendall effect during galvanic replacement reactions.” Nat. Commun. (2017) | Abstract |

| Arjan P. H. Gelissen, Alex Oppermann, Tobias Caumanns, Pascal Hebbeker, Sarah K. Turnhoff, Rahul Tiwari, Sabine Eisold, Ulrich Simon, Yan Lu, Joachim Mayer, Walter Richtering, Andreas Walther, and Dominik Wöll.”3D Structures of Responsive Nanocompartmentalized Microgels.” Nano Letters (2016) | Abstract |

Read More