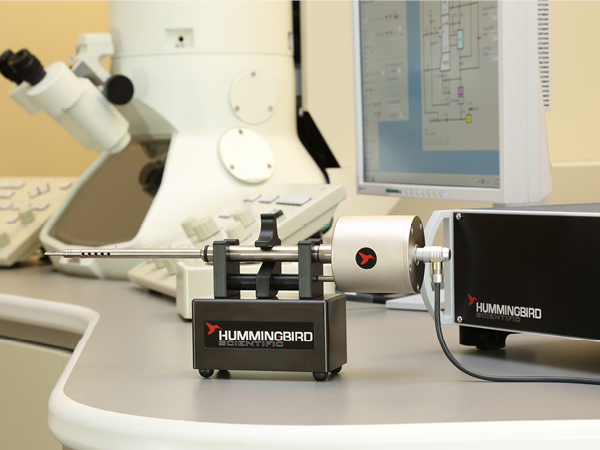

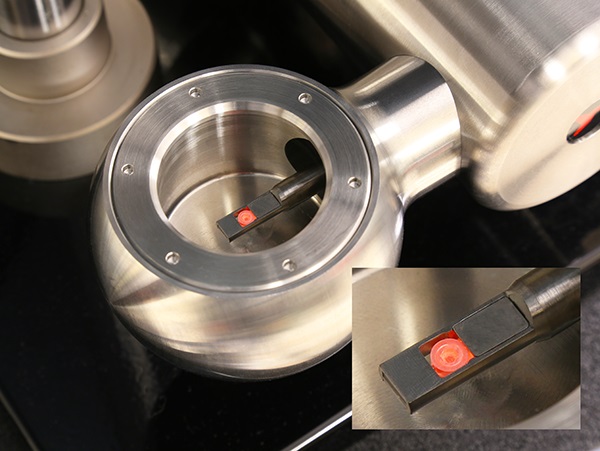

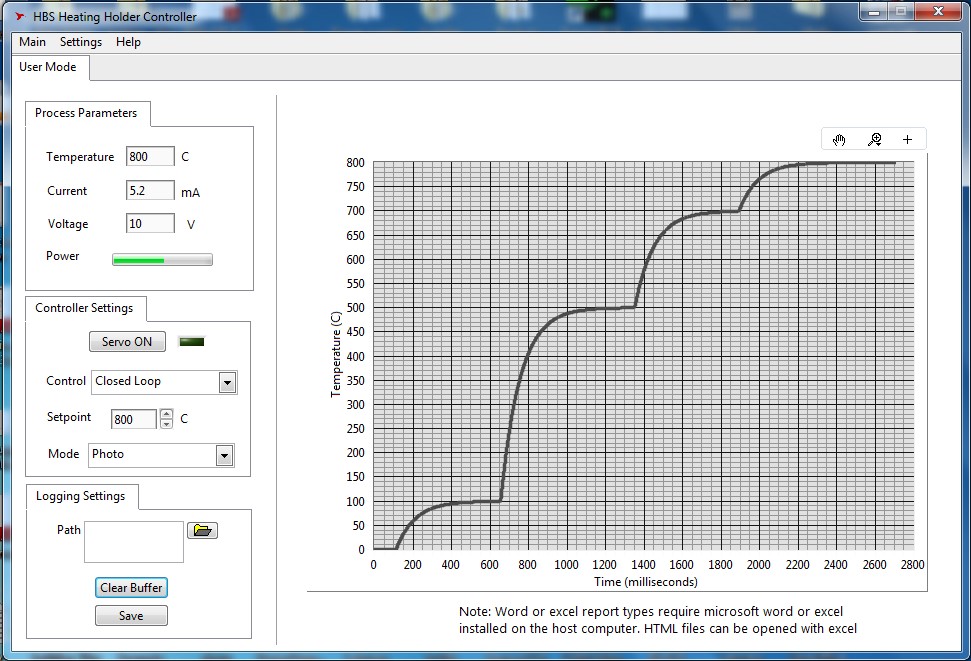

Furnace Heating

| 1500 Series | ETEM | TEM |

| Max Operating Temperature |

800°C | 1000°C |

| Settled resolution at 800ºC |

Up to TEM resolution | Up to TEM resolution |

| Temperature Measurement | Direct Thermocouple | Direct Thermocouple |

| Tilt Range | Up to ±45° depending on objective pole | Up to ±45° depending on objective pole |

| Cooling at High Temperatures | Passive Conduction (No Liquid Cooling) | Passive Conduction (No Liquid Cooling) |

| Furnace Material | Non-Magnetic and Chemically Inert | Non-Magnetic and Chemically Inert |

| TEM Compatibility | TFS/FEI, JEOL | TFS/FEI |

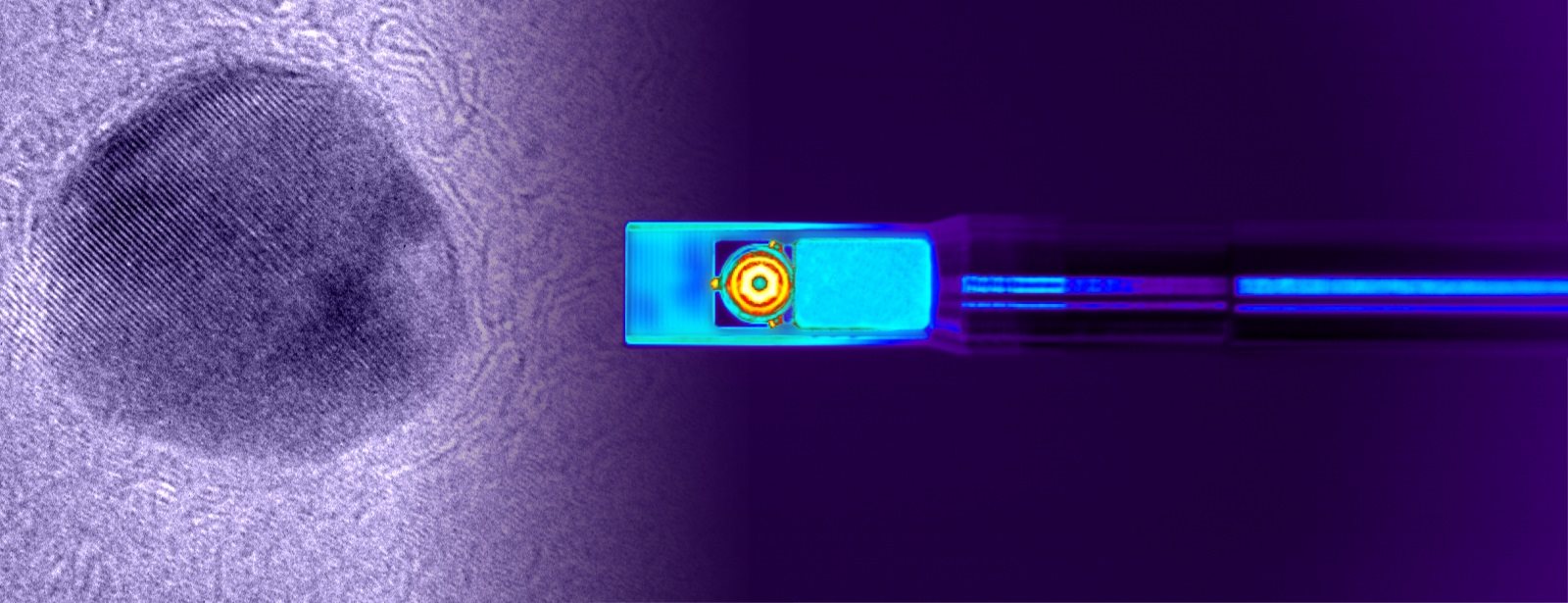

In-situ TEM Catalysis

One of the most exciting and promising areas of TEM-based research is the in-situ observation of materials interacting with gaseous environments. This research includes studies into the effect of gaseous overpressures on the shape, structure, defects, and electronic activity of a material. It is perhaps most critical to the study of catalysis because it allows researchers to observe on the atomic scale how catalysts respond to their environment while they are active.

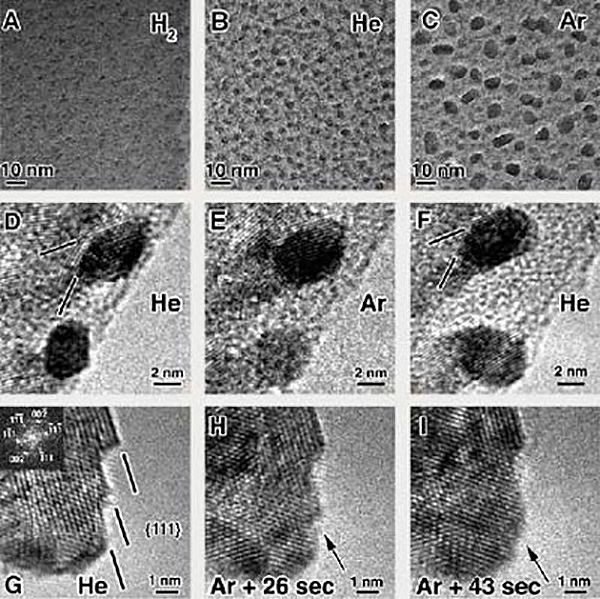

Right: Microstructural changes as a function of the gas environment of an Fe catalyst, shown in sequential high-resolution transmission electron micrographs:

- (A to C) Size evolution of Fe catalysts after 60 min under H2 (A), He (B), and Ar (C) at 500°C and 500 mtorr.

- (D to F) Series of images from the same two Fe catalyst particles held at 500°C, as the gas overpressure changes from (D) 500 mtorr He to (E) 500 mtorr Ar to (F) 500 mtorr He.

- (G to I) Series of images from a larger Fe catalyst particle along a 110 zone axis:

- (G) Image taken in 500 mtorr He at 500°C, showing very strong {111} facets. The inset diffractogram confirms the zone axis orientation.

- (H) After the introduction of Ar, local degradation of the facets begins.

- (I) With further time at 500°C in the Ar environment, the facet has been completely removed.

For all cases, the H2O with base pressure of 10-2 mtorr is present. Arrows in (H) and (I) indicate the gradual defaceting features over time.

Reference: A.R. Harutyunyan, G. Chen,T.M. Paronyan, E.M. Pigos, O.A. Kuznetsov, K. Hewaparakrama, S.M. Kim, D. Zakharov, E.A. Stach, G.U. Sumanasekera. “Preferential Growth of Single-Walled Carbon Nanotubes with Metallic Conductivity,” Science 326 (2009) pp. 116–120. Abstract

Image Copyright © 2009, American Association for the Advancement of Science

Edit

Catalysis

A high-resolution transmission electron movie of Fe catalyst as a function of gas environment shows Fe particles undergoing reversible shape changes following a switch from He/H2O to Ar/H2O gas at 500°C.

Reference: A.R. Harutyunyan, G. Chen,T.M. Paronyan, E.M. Pigos, O.A. Kuznetsov, K. Hewaparakrama, S.M. Kim, D. Zakharov, E.A. Stach, G.U. Sumanasekera. “Preferential Growth of Single-Walled Carbon Nanotubes with Metallic Conductivity,” Science 326 (2009) pp. 116–120. Abstract

Copyright © 2009, American Association for the Advancement of Science

Edit| F. F. Abdeljawad. “Microstructural evolution of thin polycrystalline metallic films under extreme conditions,”DOE Technical Report (2019) | Abstract |

| O. K. Donaldson, K. Hattar, T. Kaub, G. B. Thompson, and J. R. Trelewicz. “Solute stabilization of nanocrystalline tungsten against abnormal grain growth,”Journal of Materials Research (2017) | Abstract |

| C. A. Taylor, D. C. Bufford, B. R. Muntifering, D. Senor, M. Steckbeck, J. Davis, B. Doyle, D. Buller, and K. M. Hattar. “In Situ TEM Multi-Beam Ion Irradiation as a Technique for Elucidating Synergistic Radiation Effects,”Materials (2017) | Abstract |

| B. Muntifering, P.-A. Juan, R. Dingreville, J. Qu, and K. Hattar. “In Situ TEM Self-Ion Irradiation and Thermal Aging of Optimized Zirlo,”Microscopy and Microanalysis (2016) | Abstract |

| B. Muntifering, Y. Fang, A. C. Leff, A. Dunn, J. Qu, M. L. Taheri, R. Dingreville, and K. Hattar. “In situ Transmission Electron Microscopy He+ implantation and thermal aging of nanocrystalline iron,”J. Nucl. Mater (2016) | Abstract |

| B. Muntifering, R. Dingreville, K. Hattar, and J. Qu. “Electron Beam Effects during In-Situ Annealing of Self-Ion Irradiated Nanocrystalline Nickel,” MRS Online Proceedings Library (2015) | Abstract |

| B.R. Muntifering, A. Dunn, R.P. Dingreville, J. Qu, K.M. Hattar. “In-Situ TEM He+ Implantation and Thermal Aging of Nanocrystalline Fe,” Microscopy and Microanalysis (2015) | Abstract |

| C. Ngo, and S. Kodambaka. “In situ Microscopy Studies of Liquid Gallium Droplet Dynamics,” Microscopy and Microanalysis (2014) | Abstract |

| L. He, J.P. Chu, C.L. Li, C.M. Lee, Y.C. Chen, P.K. Liaw, P.M. Voyles. “Effects of Annealing on the Compositional Heterogeneity and Structure in Zirconium-Based Bulk Metallic Glass Thin Films,” Thin Solid Films (2014) | Abstract |

| S.M. Kim, S. Jeong, and H.C. Kim. “Investigation of Carbon Nanotube Growth Termination Mechanism by In-situ Transmission Electron Microscopy Approaches,” Carbon Letters (2013) | Abstract |

| M. Pozuelo, S. Prikhodko, X. Zhang, J. Park, R. Koc, and S. Kodambaka. “In Situ TEM Study of Chemical and Structural Transformation of Carbon Coated Titania Nanoparticles,” Microscopy and Microanalysis (2011) | Abstract |

| S.M. Kim, C.L. Pint, P.B. Amama, R.H. Hauge, B. Maruyama, E.A. Stach. “Catalyst and catalyst support morphology evolution in single-walled carbon nanotube supergrowth: Growth deceleration and termination,” Journal of Material Resolution (2010) | Abstract |

| A.R. Harutyunyan, G. Chen, T.M. Paronyan, E.M. Pigos, O.A. Kuznetsov, K. Hewaparakrama, S.M. Kim, D. Zakharov, E.A. Stach, G.U. Sumanasekera. “Preferential Growth of Single-Walled Carbon Nanotubes with Metallic Conductivity,” Science (2009) | Abstract |

Read More