How can size weakening mechanisms in nanoparticles be separated from each other?

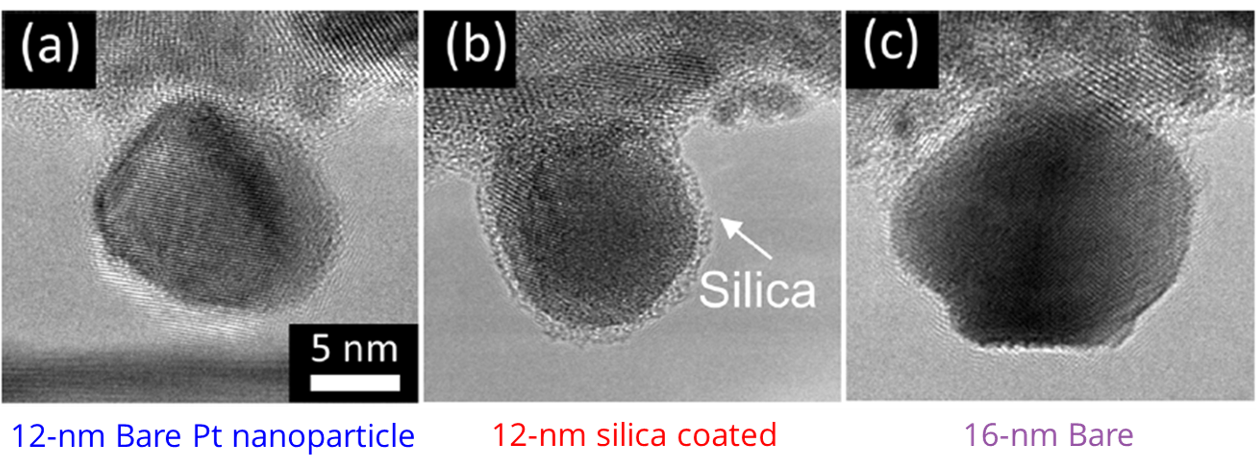

Ruikang Ding, Tevis D.B. Jacobs, and their colleagues at the University of Pittsburgh and University of California- Merced published work using the Hummingbird Scientific in-situ biasing nano-manipulator sample holder to investigate the impact of geometric effects and surface diffusion on the strength of Pt nanoparticles of decreasing size. The factory-customized holder featured an atomic force microscope probe for precise low-load sensing during incremental compression of 12-nm Pt nanoparticles, both bare and silica-coated, as well as 16-nm Pt nanoparticles.

Figure 1. TEM bright field images of a) smaller bare nanoparticles with diameter ~12 nm, b) smaller silica coated nanoparticles with diameter ~12 nm, c) larger bare nanoparticles with diameter ~16 nm. Copyright 2024 American Chemical Society

Geometric effects such as surface curvature may lead to a reduced barrier for nucleation of dislocations, which is typically how nanoparticles in this size range fail. It has been suggested that faster surface diffusion on smaller particles can also lead to dislocation nucleation. Thermodynamics calculations indicate that strengthening due to size increase should be equal to the strengthening effect of a silica coating if surface diffusion were the dominant factor in dislocation formation and weakening at smaller sizes.

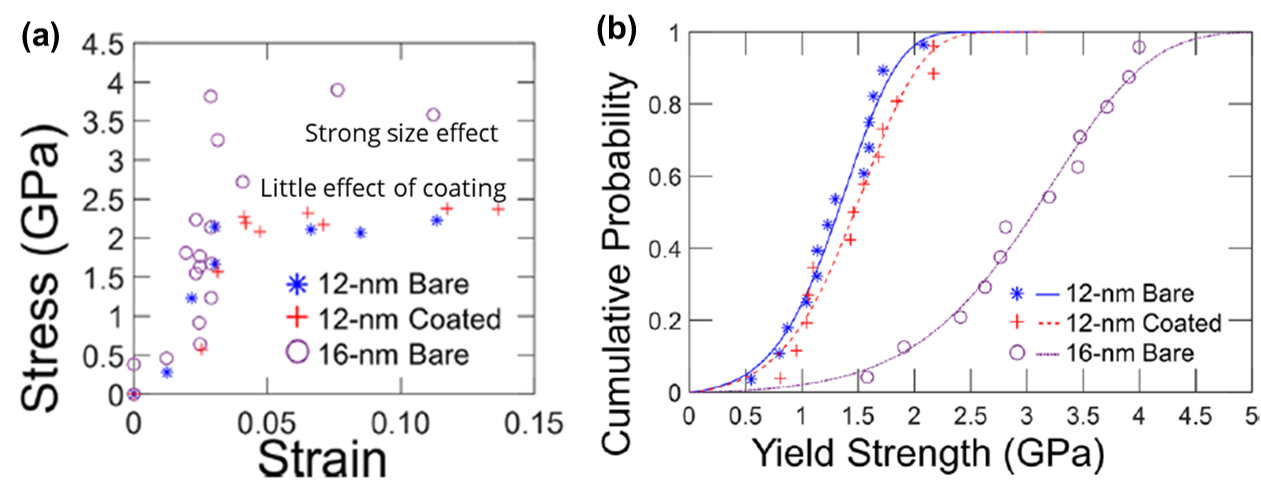

Figure 2. a) True stress-strain curves for all nanoparticles tested. b) Cumulative distribution functions showing yield strengths corrected for stress concentration for all tested nanoparticles. Copyright 2024 American Chemical Society

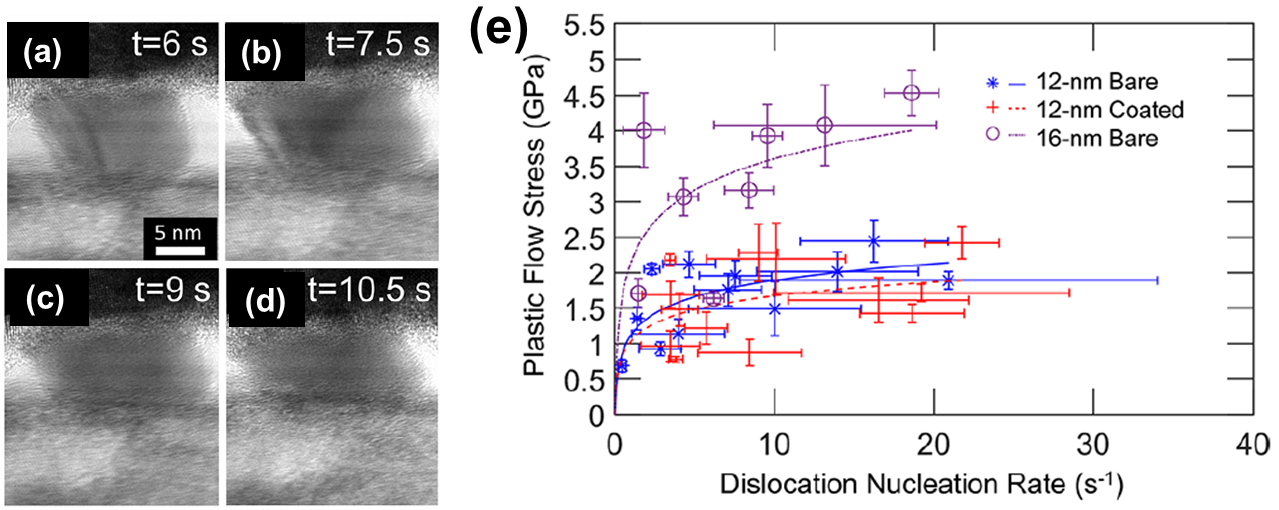

The series of compressions revealed a strong dependence on size with a 100% increase in mean yield strength and little to no strengthening effect of the coating. In-situ compression results combined with an analysis of dislocation nucleation under stable plastic flow demonstrate a stronger influence of geometric factors on nanoparticle strength than surface diffusion.

Figure 3. a–e) TEM bright field of plastic flow analysis at various compression times. e) Dislocation nucleation rate computed from the plastic flow stress and plastic strain rate extracted using Arrhenius equation. Copyright 2024 American Chemical Society

Reference: Ruikang Ding, Soodabeh Azadehranjbar, Ingrid M. Padilla Espinosa, Ashlie Martini, and Tevis D. B. Jacobs, ACS Nano 18 (5) 4170–4179 (2024) DOI: 10.1021/acsnano.3c09026

Full paper Copyright © 2024 American Chemical Society

View All News