How does size determine the strength and deformation mechanisms of nanoparticles under compression?

Soodabeh Azadehranjbar, Tevis D.B. Jacobs, and their colleagues at the University of Pittsburgh and University of California- Merced published work using the Hummingbird Scientific in-situ biasing nano-manipulator sample holder to investigate size effects and surface diffusion in platinum nanoparticle compression. The factory-customized holder featured an atomic force microscope probe for sensing of the applied load during incremental compression of particles as small as 6nm in diameter while simultaneously tracking their structural evolution.

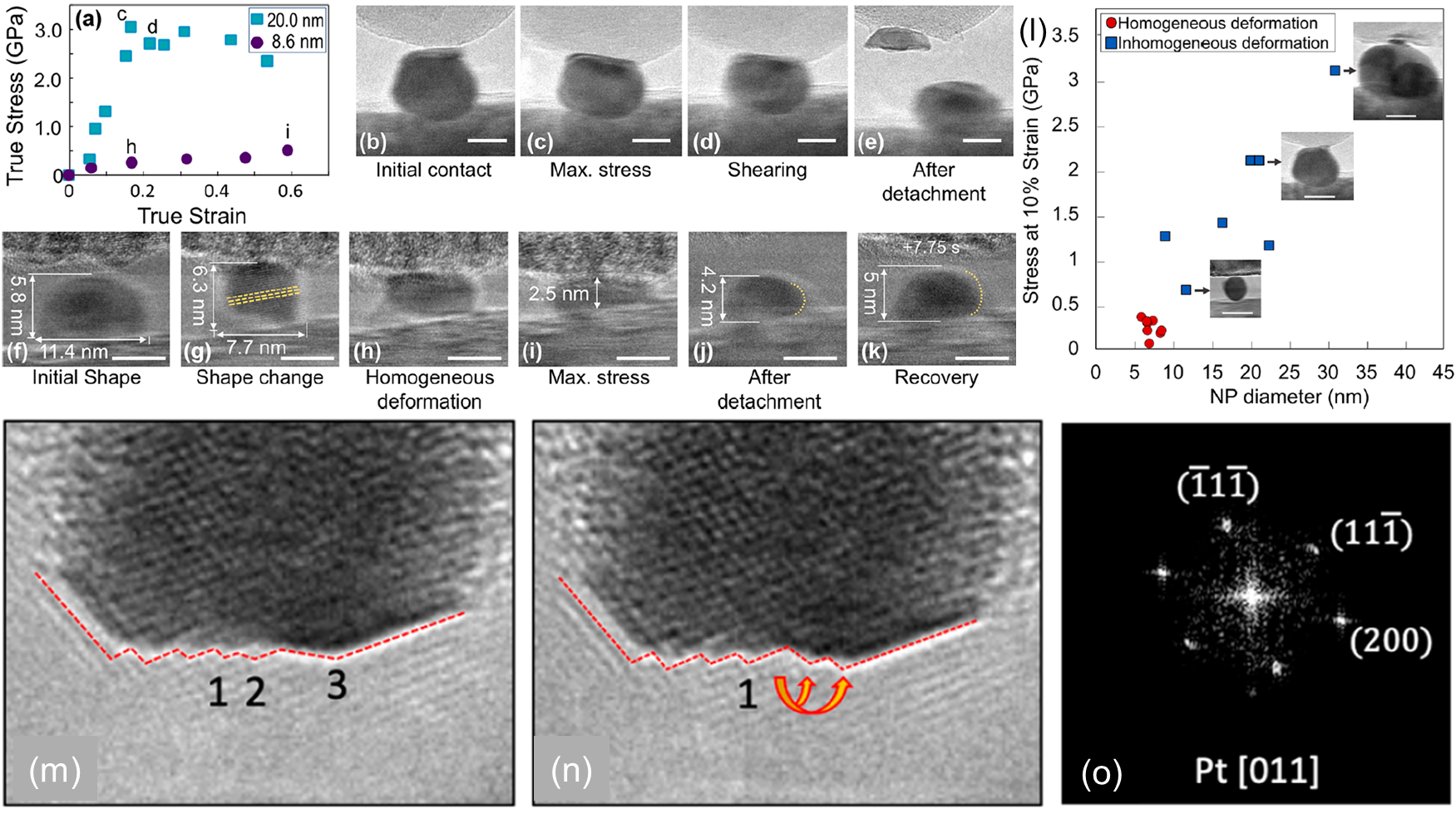

Figures showing a) Stress strain for two representative particles. b-e) Deformation microscopy of 20-nm particle from (a). f-k) Deformation microscopy of 8.6-nm particle from (a). l) Strength of particles represented by the stress at 10% strain vs NP diameter. Scale bars are 2 nm. m-n) Surface steps from two consecutive frames showing surficial atomic hopping events. o) Fourier transform indicating crystal orientation. Copyright 2023 American Chemical Society

The series of compressions revealed a transition in deformation behavior below ~9nm, from localized displacive shearing in larger particles to fully homogeneous flow. This nanoscale regime exhibited substantial strains up to 60% with complete shape recovery, mediated by surface diffusion from facet to facet. TEM dynamically captured the atomic rearrangements and deformed shapes, offering new insights into the competing roles of dislocation activity and atomic migration, and enabling quantification of size-dependent mechanical trends and correlating measured strengths with underlying atomic-level processes. The technique shows promise for investigating mechanical stability and deformation mechanisms in nanoparticles aimed at nanoelectronic, plasmonic, and catalytic applications.

Reference: Soodabeh Azadehranjbar, Ruikang Ding, Ingrid M. Padilla Espinosa, Ashlie Martini, and Tevis D. B. Jacobs, ACS Nano 17 (9) 8133–8140 (2023) DOI: 10.1021/acsnano.2c11457

Full paper Copyright © 2023 American Chemical Society

View All News