How does indium nanoplate formation differ from other metal nanoplates?

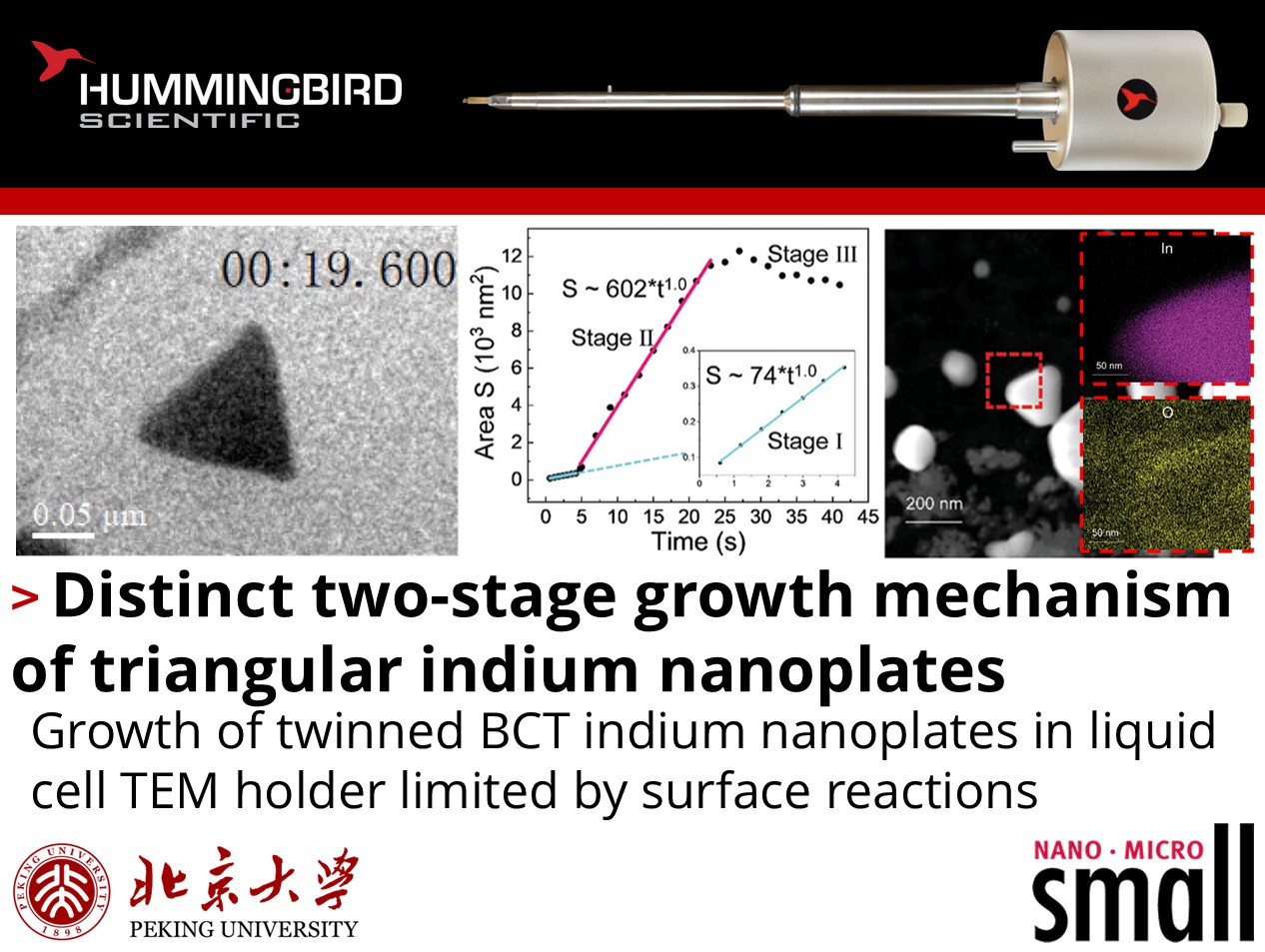

Jiamin Tian, Qing Chen, and their colleagues at Peking University published recent work using their Hummingbird Scientific in-situ liquid flow TEM sample holder to investigate the growth mechanisms of indium nanoplates. The team combined in-situ imaging under TEM, ex-situ HAADF-STEM characterization and chemical analysis with energy dispersive X-ray spectroscopy (EDS), and density functional theory (DFT) calculations to construct a complete understanding of the structural transition of metal nanoplates during growth.

Quantitative analysis of captured video revealed growth of indium nanoplates proceeds in two steps, which differs from previously reported metal nanoplate systems. First a gradual transformation from face-centered cubic (FCC) structure to body-centered tetragonal phase (BCT), followed by faster growth from BCT seeds into triangular nanoplates. The nanoplates form with a {110}-twin which gives them their triangular shape. The shape evolution of a truncated triangle is also characterized, with growth rate of the truncated edge dependent on the number of re-entrant grooves. The liquid holder enabled the environmental conditions necessary for growth of these indium nanoplates, allowing in-situ characterization of growing microstructures and isolation of growth regimes. The holder and accompanying methodology can be applied to other nanoplate systems, guiding controlled synthesis of uniquely structured nanocrystals.

Reference:

Jiamin Tian, Dongying Lin, Xuan Li, Kewei Wang, Bocheng Yu, Menglan Li, Shimin Hou, Zhihong Li, Qing Chen, Small XX 2400680 (2024) DOI: 10.1002/smll.202400680

Full paper Copyright © 2024 Wiley-VCH GmbH

View All News