How can graphene be used as a working electrode in liquid-electrochemical microscopy?

Saltanat Toleukhanova, Vasiliki Tileli, and their colleagues at EPFL published recent work characterizing graphene as a working electrode for CO2 electroreduction (CO2ER) of Cu nanocatalysts with the Hummingbird Scientific Generation V bulk liquid-electrochemical SEM system. The robust three-layer graphene membrane, which served as the sample carrier, working electrode, and liquid sealing membrane, was applied to the chip via a wet transfer process.

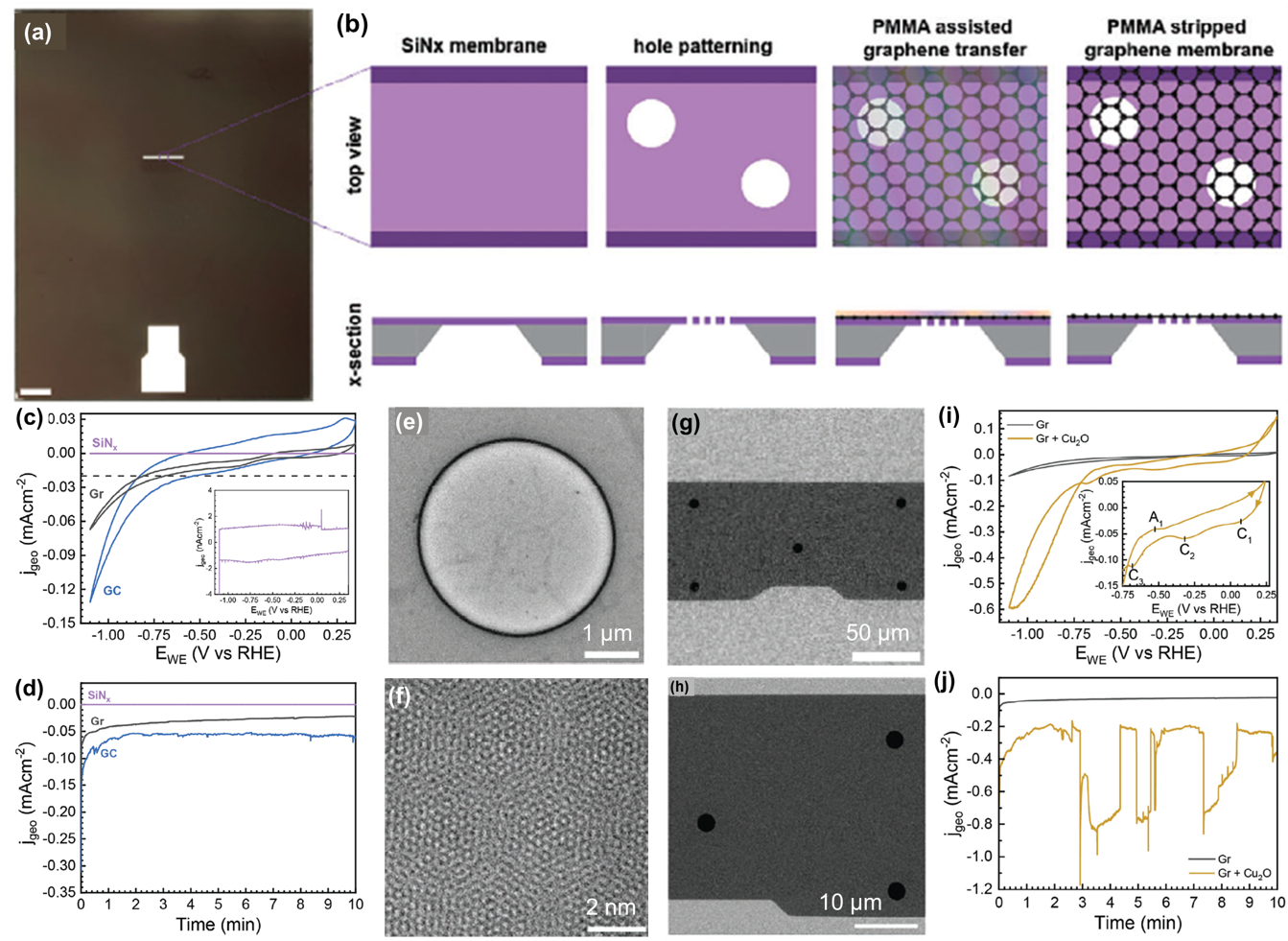

a) Optical microscope image of electrochemical chip. b) Schematic of graphene membrane preparation via wet transfer process. c) Cyclic voltammetry (CV) of SiNx, graphene, and glassy carbon comparing performance and inert potential range. d) Chronoamperometry (CA) at -1.1 V vs. RHE for SiNx, graphene, and glassy carbon. e) TEM image of graphene transferred onto hole. f) HR-TEM image of graphene membrane. i) CV of bare graphene and Cu2O nanocubes. j) CA -1.1 V vs. RHE for bare graphene and Cu2O nanocubes. Copyright © 2024 The Authors. Advanced Materials published by Wiley-VCH GmbH

Electrochemical liquid-phase SEM (ec-LPSEM) enabled imaging of Cu nanocube degradation processes under CO2 reductive conditions. Cyclic voltammetry (CV) plots indicated a wider inert cathodic range for the graphene working electrode than glassy carbon. A synergistic effect between the electron beam and the applied potential affected the stability of the graphene membrane. Keeping the probe current low enabled imaging of nanocube degradation and secondary particle deposition at the CO2ER operating potential of -1.1 V vs. RHE. The team demonstrate the advantages of the graphene working electrode in liquid electron microscopy cells, towards multiscale imaging of electrochemically-driven processes.

Reference:

Saltanat Toleukhanova, Tzu-Hsien Shen, Chen Chang, Swathilakshmi Swathilakshmi, Tecla Bottinelli Montandon, and Vasiliki Tileli, Adv. Mater. 36 (16) 2311133 (2024) DOI: 10.1002/adma.202311133

Full paper Copyright © 2024 The Authors. Advanced Materials published by Wiley-VCH GmbH

View All News