How does the Biasing Manipulator reveal the effect of metal nanoparticle size on their strength and mechanical behavior under compression?

Ruikang Ding and Tevis D.B. Jacobs of the University of Pittsburgh, along with Ashlie Martini of the University of California, Merced, have used the Hummingbird Scientific Biasing Manipulator TEM sample holder to directly observe failure mechanisms of Au, Ag, and Pt nanoparticles under compression, enabling the measurement of nanoparticle strength as a function of their size.

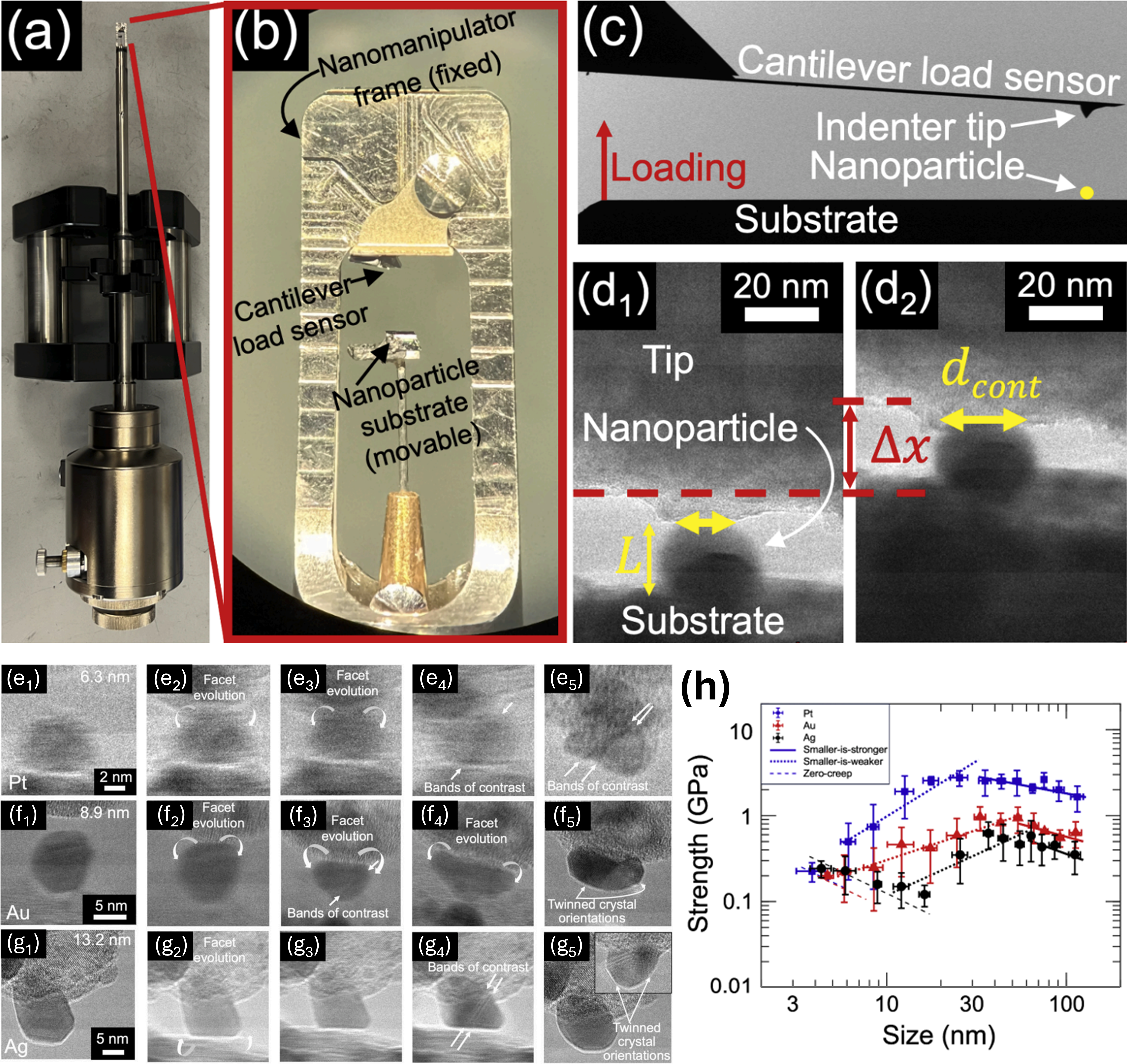

(a) The Hummingbird Scientific Biasing Manipulator TEM sample holder used to perform over 250 in situ compression tests. (b) The experimental setup includes a cantilever load sensor (AFM probe) mounted on a rigid frame and a nanoparticle-decorated substrate mounted on a piezo-controlled movable stage. (c) The nanoparticle is brought into contact with the load sensor, enabling controlled compression. (d) Real-time TEM imaging allows direct measurement of the nanoparticle’s height (L) and contact diameter (dcont). (d1–d2) The applied force is calculated from the cantilever’s stiffness and its displacement (Δx), enabling quantitative stress and strain analysis during deformation. (e-g) Video frames from compression tests on intermediate-sized platinum (e1-e5), gold (f1-f5), and silver (g1-g5) nanoparticles reveal transitional deformation behavior. Each sequence shows the nanoparticle before contact (e1, f1, g1), during progressive loading(e2-e4, f1-f5, g1-g5), and after unloading (e5, f5, g5). Displacive deformation is evident from contrast bands and twinning, while facet evolution suggests concurrent diffusive deformation. Post-test images confirm the presence of twinned crystal structures, indicating that both mechanisms were active during compression. (h) The strength–size plot presenting all measured data points across the full range of nanoparticle sizes and deformation mechanisms. To improve clarity, particles are grouped into size bins, with each bin showing the average strength and standard deviation. The fitted trend lines illustrate the observed size-dependent mechanical behavior across different deformation regimes.

Over 250 compression tests revealed how deformation mechanisms evolve with particle size. Larger nanoparticles (15–130 nm) deformed via surface dislocation nucleation, showing increased strength with decreasing size until a peak around 30–60 nm, followed by weakening. High-resolution imaging confirmed twinning and stacking faults and extracted activation parameters matched partial dislocation behavior. Smaller particles transitioned to mixed plastic and diffusive deformation. Intermediate sizes (5–15 nm) showed reduced elastic modulus and lacked clear yield points. Facet evolution and twinning indicated coexisting displacive and diffusive mechanisms, with surface diffusion contributing to softening. The smallest nanoparticles (3–5 nm) deformed through surface atom migration, best described by a time-independent zero-creep model. Load-hold experiments confirmed deformation was not time-dependent, contradicting classical creep models. A thermodynamic zero-creep framework accurately described stress–strain behavior and predicted a smaller-is-stronger trend in the diffusive regime.

The Hummingbird Scientific Biasing Manipulator TEM sample holder enabled precise, real-time force application and deformation measurement, revealing distinct size-dependent mechanisms in noble-metal nanoparticles, contributing to a deeper understanding of nanoscale mechanical behavior and informing future materials design strategies.

Reference: Ruikang Ding, Ashlie Martini, Tevis D.B. Jacobs. Acta Materialia, 2025, 293, 121092. DOI: 10.1016/j.actamat.2025.121092

Full paper from Acta Materialia under the Creative Commons license

View All News