Curious why observed adhesion between nanoscale components deviates from well-established models?

Andrew Baker, Tevis D.B. Jacobs, and their colleagues at the University of Pittsburgh and University of California- Merced published work using the Hummingbird Scientific in-situ biasing nano-manipulator sample holder to study nanoscale adhesion. The holder was factory customized to include an atomic force microscope probe, which allowed for sensing of the applied load.

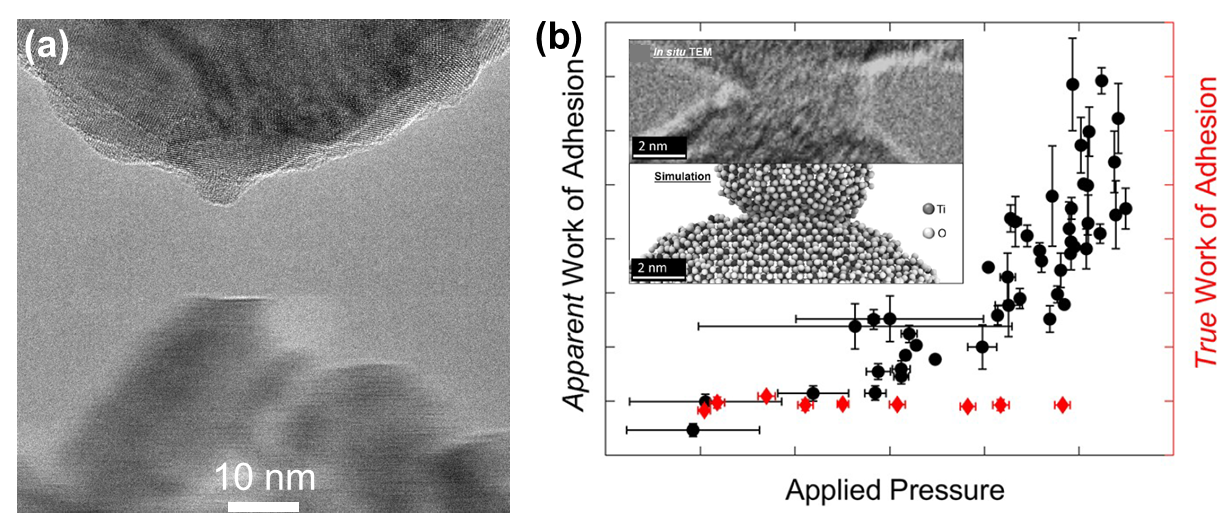

a) In-situ TEM image of AFM tip approach. b) Apparent work of adhesion applying only fracture mechanics models compared to the true work of adhesion where strength-controlled separation is considered. Inset with contact TEM images and simulation. Copyright 2022 American Chemical Society

With precise position control over the nano-manipulator probe, over 135 nanoscale adhesion tests of technologically relevant materials like titanium dioxide and silicon-diamond were conducted and combined with atomistic simulations. The mechanisms which govern adhesion increase with applied load were shown to follow a transition from fracture-controlled separation to strength-controlled. If fracture-controlled mechanisms are applied for higher loads, the apparent work of adhesion is overpredicted by a factor of 7. The true work of adhesion is unchanged with loading, with the apparent increase in adhesion with applied load resulting from an increase in contact surface area. These fundamental insights will guide future innovation in nanomanufacturing and photocatalysis.

Reference: Andrew Baker, Sai Bharadwaj Vishnubhotla, Rimei Chen, Ashlie Martini, Tevis D.B. Jacobs, Nano Letters 22 (14) 5954–5960 (2023) DOI: 10.1021/acs.nanolett.2c02016

Full paper Copyright © 2022 American Chemical Society

View All News