How does solution chemistry influence the etching of palladium nanorods?

Xiaoming Ma, Chuanhong Jin, and their colleagues at the East China University of Science and Technology, the South China Agricultural University, and Zhejiang University used their Hummingbird Scientific in-situ liquid flow TEM sample holder to investigate near and non-equilibrium oxidative etching of penta-twinned palladium nanorods and the influence of solution chemistry. The experiments were compared and reproduced with flask-system based etching experiments to directly correlate with liquid cell transmission electron microscopy (LC-TEM) results.

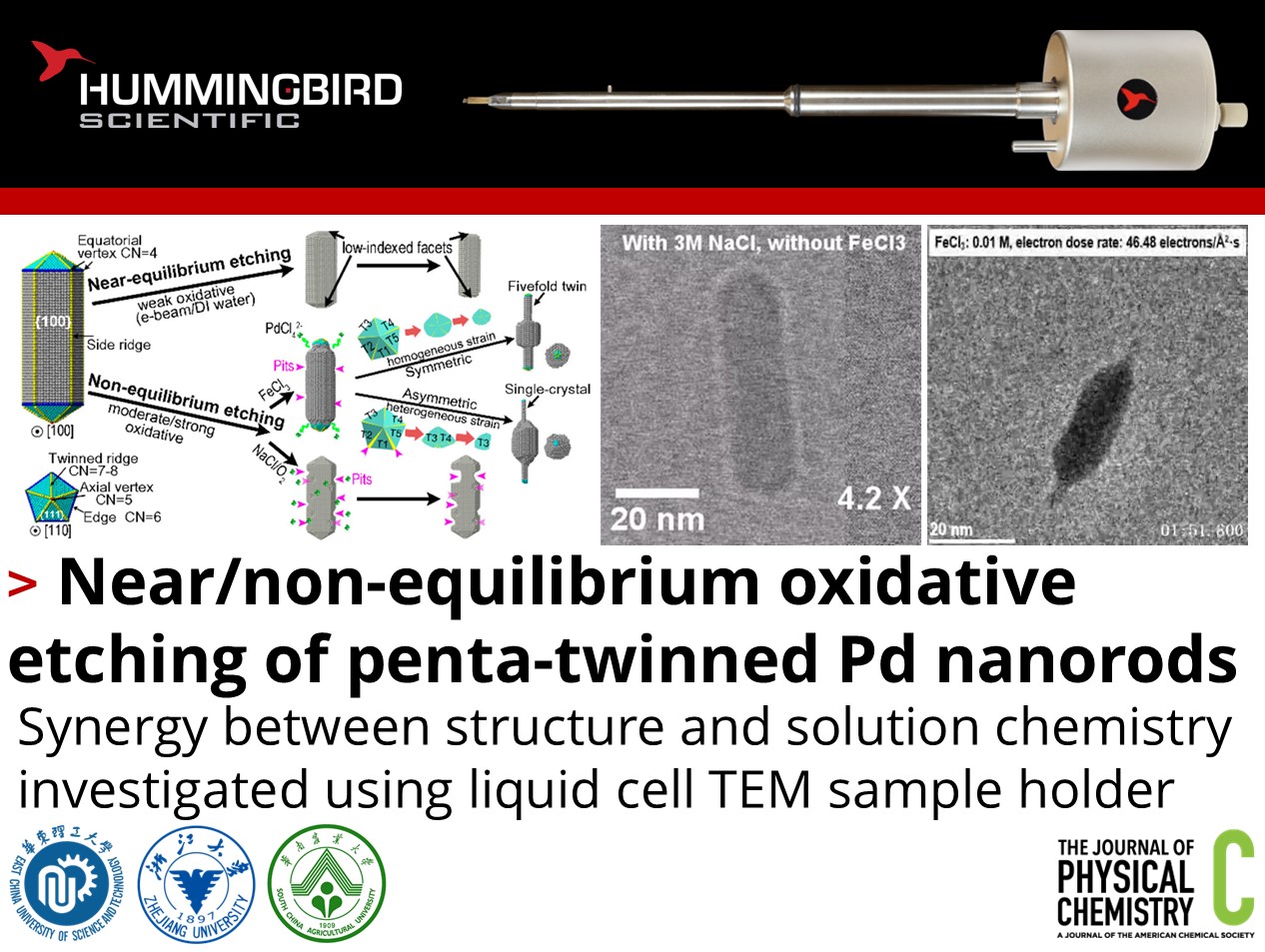

a) Schematic illustrating the near-equilibrium and nonequilibrium etching mechanism pathways for penta-twinned Pd nanorods. b) Video of weakly oxidative near-equilibrium etching. c) Video of moderately oxidative nonequilibrium etching in NaCl solution. c) Video of strongly oxidative nonequilibrium etching in FeCl3 solution. Copyright © 2021 American Chemical Society

Three solutions were used in tandem with the e-beam to apply oxidative etching conditions. DI water for weakly oxidative (near equilibrium), NaCl solution for moderately oxidative and FeCl3 solution for strongly oxidative (both non-equilibrium) conditions. Near equilibrium, etching proceeds slowly at low-indexed facets forming flat ends. In NaCl, pitting occurs as the material is etched away. In FeCl3 either the original structure is retained (symmetric etching) or the structure proceeds through fourfold-, threefold-, twofold-twinned and single-crystal structure as it is dissolved. The difference is attributed to the structural defects and resulting strain distribution. The work provides insights into the synergetic roles of solution chemistry on etching of nanoparticles for improved nanocatalyst synthesis and operating conditions.

Reference: Xiaoming Ma, Fang Lin, Xin Chen, Chuanhong Jin, The Journal of Physical Chemistry C (2021) DOI: 10.1021/acs.jpcc.0c11200

Full paper Copyright © 2021 American Chemical Society

View All News