How can tedious morphological analysis of nanoparticles be automated?

Muhammad Ishfaq Hussain, Muhammad Aasim Rafique, Moongu Jeon, and their colleagues from Gwangju Institute of Science and Technology, King Faisal University, and the Korea Basic Science Institute published work using the Hummingbird Scientific In-situ Liquid Flow TEM sample holder to grow spiky Au nanoparticles (SNPs) in a liquid cell via radiolysis under transmission electron microscopy (TEM). The team integrated a deep neural network (DNN) to automatically segment the growth of the nanoparticles and an auxiliary loss function to measure the spikes in border regions.

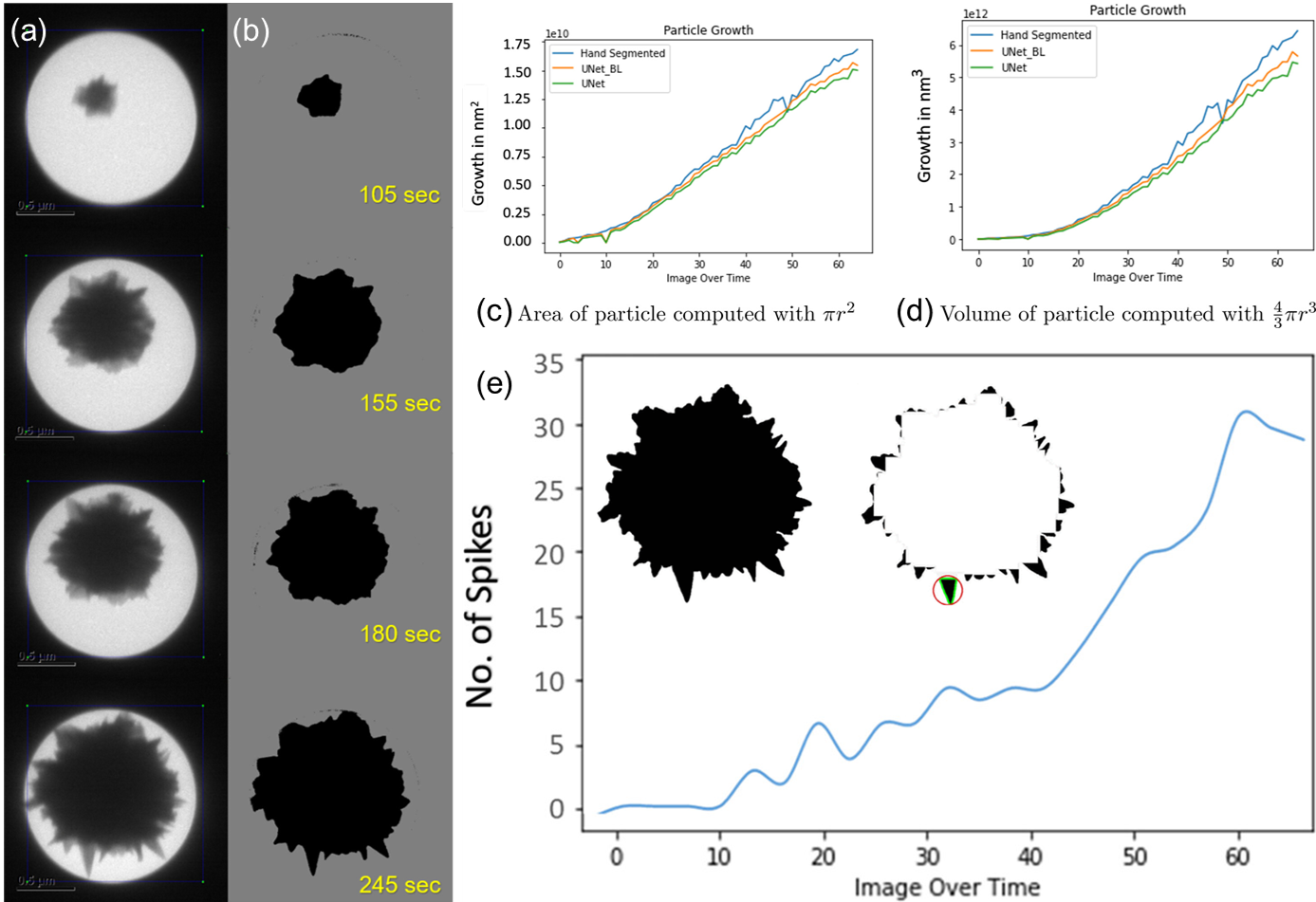

Segmentation results of selected frames during radiolytic growth of spiky nanoparticle using the proposed network: a) particle growth over time in bright-field LCTEM, b) segmented result. Plots of growth of particle over the course of experimentation: c) area of the particle, d) volume of the particle. e) Number of spikes on the particle determined by the loss function over the course of experimentation. Inset with segmentation of spikes isolated near the border region. Copyright © 2023 The Authors. Published by American Chemical Society. This publication is licensed under CC-BY-NC-ND 4.0.

The Hummingbird Scientific liquid holder enabled in-situ imaging of SNP growth within the TEM during radiolysis. Particle segmentation of these images were used to generate statistics for growth and morphology of a nanoparticle over the course of its formation. During the in-situ experiment, the SNP growth automatically measured by the DNN agreed with manually segmented images and was able to accurately segment the spikes in real-time. The network proved to be a useful tool for efficiently characterizing SNP growth and morphology and paves the way for further integration with microscope hardware via an FPGA implementation.

Reference: Muhammad Ishfaq Hussain, Muhammad Aasim Rafique, Wan-Gil Jung, Bong-Joong Kim, Moongu Jeon, ACS Omega 8 (20) 17834-17840 (2023) DOI: 10.1021/acsomega.3c00783

Full paper Copyright © 2023 The Authors. Published by American Chemical Society. This publication is licensed under CC-BY-NC-ND 4.0.

View All News