How can liquid metal coatings improve battery performance?

Supriya Koul, Akihiro Kushima, and their colleagues at University of Central Florida and Honda R&D Co. published work using their Hummingbird Scientific in-situ biasing nano-manipulator TEM sample holder to perform in-situ battery performance testing on lithium metal LiNi1/3Co1/3Mn1/3O2 (NCM) cathodes coated with a gallium-based liquid metal (LM) layer. The effect of LM layer was observed in situ by transmission electron microscopy (TEM) and optical microscopy. The solid-electrolyte interphase (SEI) was characterized using XPS.

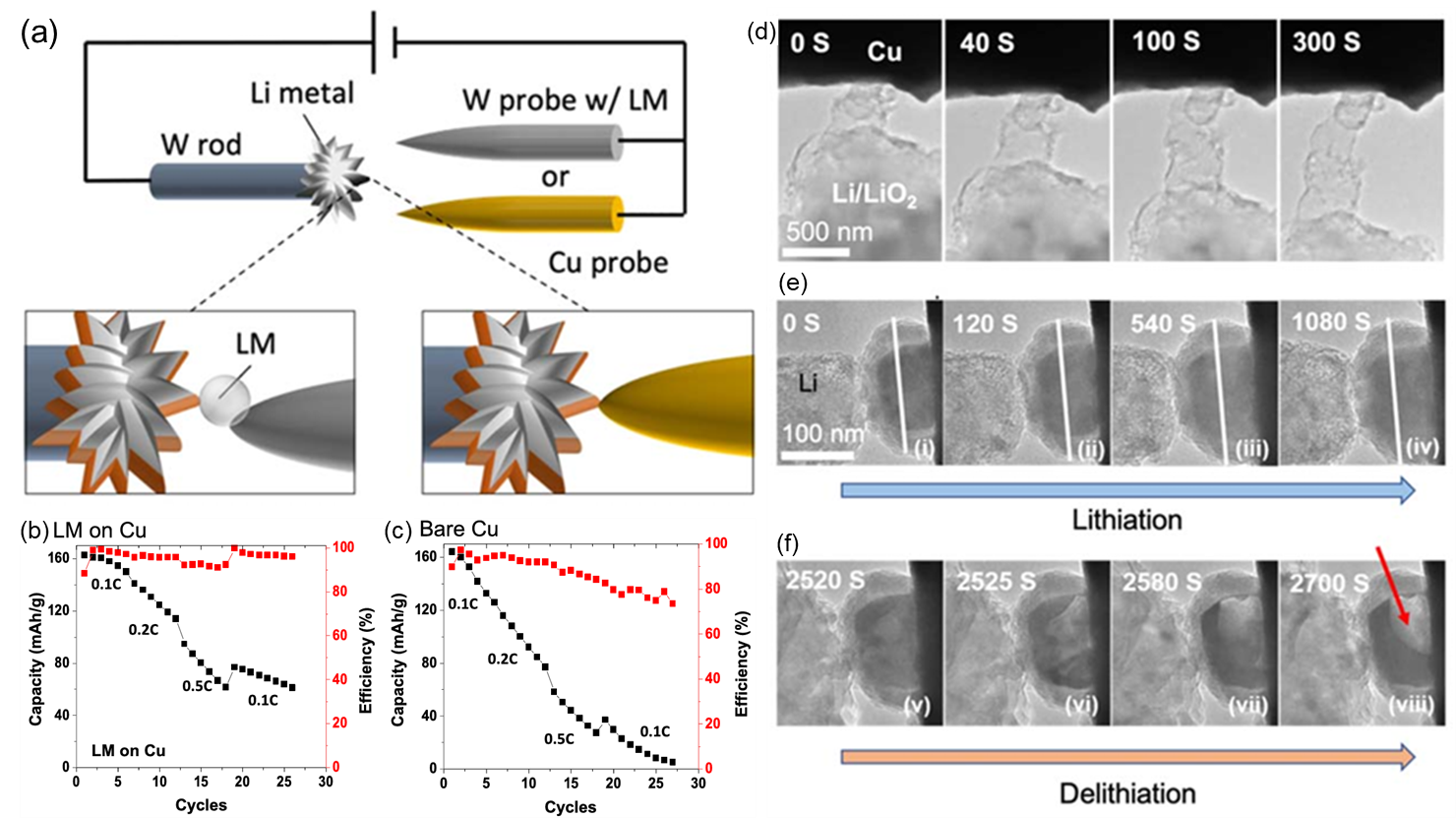

a) Schematic diagram of the in-situ TEM setup with two cases: LM on W and Cu. Rate performance of full cells using NCM cathode and Cu current collector b) with and c) without LM coating. d) Lithium plating on Cu. e) lithiation and f) delithiation of LM nanoparticles. Copyright © 2022 The Author(s). Published on behalf of The Electrochemical Society by IOP

LM nanoparticles were drop casted onto the probe of the nano-manipulator, which was brought into contact with the Li metal oxide cathode. Electrochemical testing of the LM coated electrode indicated a reduction of galvanostatic charge-discharge overpotentials compared to an un-coated bare current collector. The LM layer also facilitated the decomposition of dendritic lithium, slowing degradation of battery interface connectivity. The in-situ technique and demonstration of improved wettability of lithium using LM will improve solid-state battery cycle performance and lifetime.

Reference: Supriya Koul, Yoshiyuki Morita, Fumika Fujisaki, Hiroshi Ogasa, Yoshiya Fujiwara and Akihiro Kushima, J. Electrochem. Soc. 169 (2) 020542 (2022) DOI: 10.1149/1945-7111/ac4ea5

Full paper Copyright © 2022 The Author(s). Published on behalf of The Electrochemical Society by IOP

View All News