Can nanoparticle depositions improve the long-term stability of photocathodes in acidic environments?

Ji Hoon Choi and Hyung Koun Cho, along with their colleagues at Sungkyunkwan University and the University of Pennsylvania, published recent results investigating a method for optimizing photocathodes for lifetime and catalytic activity using their Hummingbird Scientific in-situ liquid flow TEM sample holder. The response to electrical cycling was measured alongside in-situ imaging and chemical mapping of the Rh2P nano particles synthesized by photoilluminated redox deposition (PRoD).

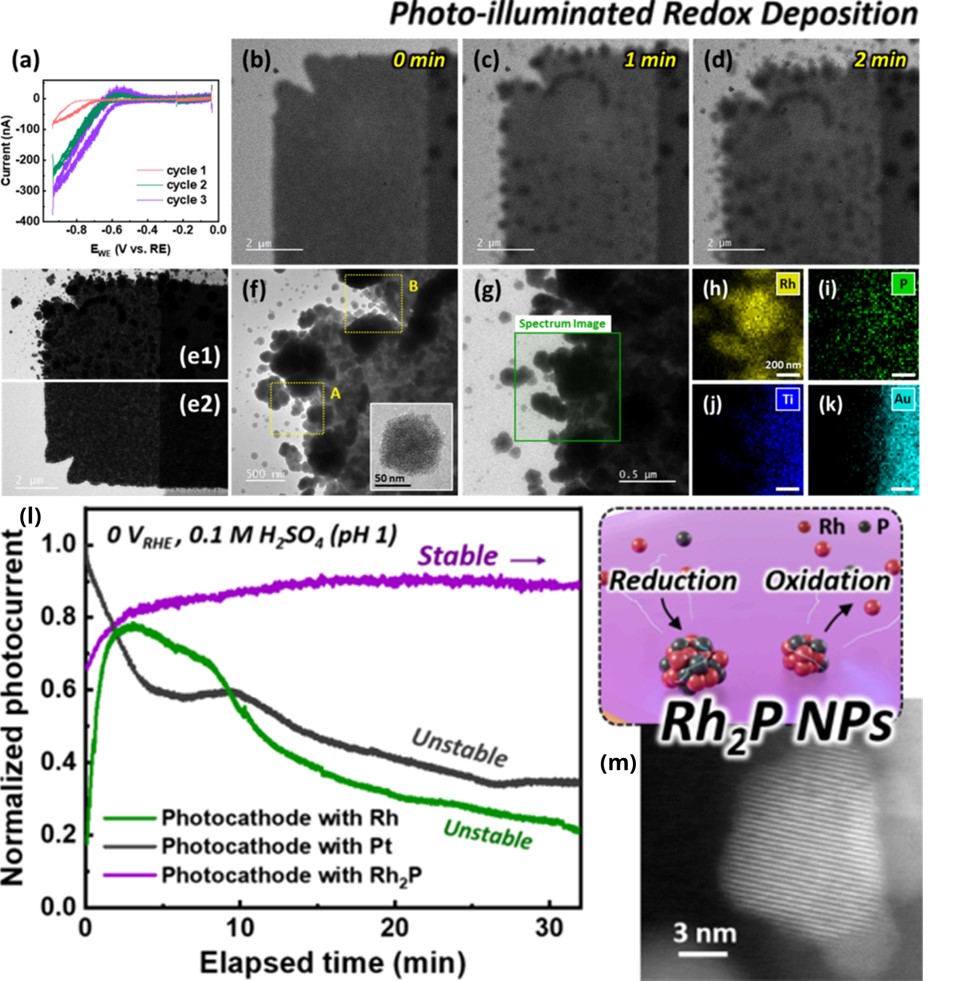

Figures showing a) CV of an Au electrode coated with 5 nm TiO2. b) In situ STEM image of Au chip filled with Rh and P precursors, and Rh2P growth evolution after voltage application for (c) 1 and (d) 2 min. e) STEM images of the working electrode (e2) before and (e1) after Rh2P deposition. f) HRTEM image taken after liquid removal (g) High-resolution image and (h−k) EDS mapping for Rh, P, Ti, and Au elements. l) Photocurrent from acidic cell with Ph2P particles compared to just Ph and Pt. m) Atomic resolution image of nanoparticles. Copyright 2024 American Chemical Society.

The in-situ deposition resulted in 5-10 nm particles on 30-nm thick TiO2. Cyclic voltammetry indicated improved photocurrent density, and reduced mass in solution was measured after chronoamperometry, indicating improved resistance to catalyst degradation. The stability under photoelectrochemical (PEC) water splitting also maintained 93% of its performance over a span of 22 hours in acidic solution. The measurements collectively indicate that the deposited nanoparticles facilitate rapid electron transport into the electrolyte, and will inform future optimization of catalyst coatings for stability, efficiency, and cost.

Reference:

Ji Hoon Choi, Hak Hyeon Lee, Sungho Jeon, Swagotom Sarker, Dong Su Kim, Eric A. Stach, and Hyung Koun Cho, ACS Appl. Mater. Interfaces 16 (17) 21953–21964 (2024) DOI: 10.1021/acsami.4c02147

Full paper Copyright © 2024 American Chemical Society.

View All News