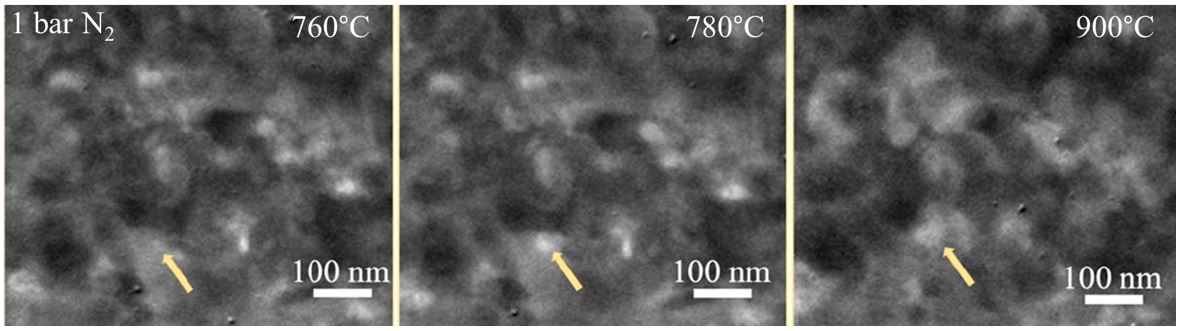

Recently, the researchers from Rensselaer Polytechnic Institute (RPI) studied the mechanism of corrosion in nickel-based Inconel-625 alloy using high-temperature molten chloride (MgCl2-NaCl-KCl). The study performed using Hummingbird Scientific’s Gas Cell TEM holder system demonstrates the initiation and acceleration of corrosion in the inter-granular region of the alloy film when exposed to air or moisture. The work is published in the Journal of The Electrochemical Society.

The work presented here using the Gas Cell TEM holder presents a unique methodology to perform control monitoring of high-temperature corrosion processes in the ambient condition without introducing significant H2O and N2 into the sample chamber.

Reference: Prachi Pragnya, Daniel Gall, and Robert Hull. “In Situ Transmission Electron Microscopy of High-Temperature Inconel-625 Corrosion by Molten Chloride Salts,” Journal of The Electrochemical Society (2021). Full Paper

View All News