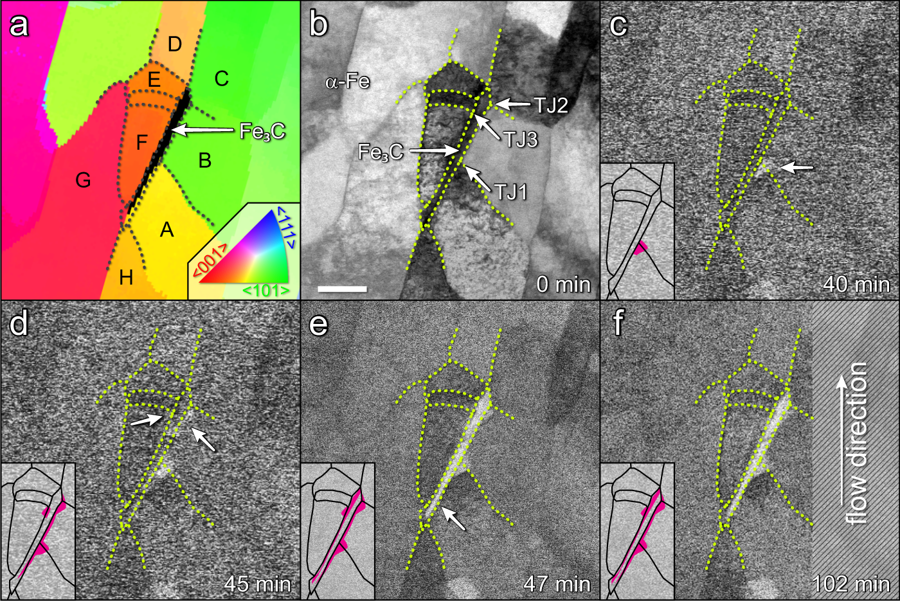

Researchers from Aramco Services Company, Idaho National Laboratory and Sandia National Laboratory have demonstrated the localized corrosion events in “real world” sample of pipeline steel using Hummingbird Scientific’s Liquid Cell TEM platform. The results published in npj Materials Degradation presents new insights into the nanoscale corrosion of low-carbon steel in wet environments, which have traditionally relied on empirical understanding based on bulk scale data.

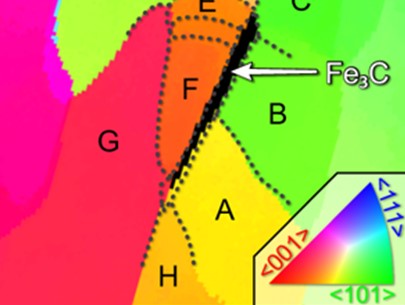

Corrosion behavior in steel has generally been understood based on two principles: bulk scale uniform corrosion and empirical interpretation of localized corrosion. Direct evidence showing the local corrosion processes is key. Here, the researchers used liquid cell TEM system and studied thin transparent sample from the bulk exterior of a 1018 steel industrial pipe in an aqueous electrolyte solution of pH 6.1. The data showed initiation of corrosion at a site of interfacial heterogeneity, which is a triple junction formed by the intersection of two ferrite grains and isolated cementite inclusion. The work presents critical insights that could help in predicting corrosion events with robust models.

Reference: Steven C. Hayden, Claire Chisholm, Rachael O. Grudt, Jeffery A. Aguiar, William M. Mook, Paul G. Kotula, Tatiana S. Pilyugina, Daniel C. Bufford, Khalid Hattar, Timothy J. Kucharski, Ihsan M. Taie, Michele L. Ostraat and Katherine L. Jungjohann. “Localized corrosion of low-carbon steel at the nanoscale,” npj Materials Degradation (2019). DOI: 10.1038/s41529-019-0078-1

View All News